The quality of building material used to construct any kind of structure plays a determining role in maintaining its durability. High quality building material ensures safety of the building and enhances its resistance against adverse climatic changes. Therefore, testing of building material, prior to its usage in construction, becomes of grave importance for construction material manufacturers. Materials testing lab is sometimes called an independent testing laboratory, and it deals primarily with testing, evaluating, and monitoring materials and processes used in construction.

The materials testing laboratory of the Civil Engineering department was setup in the year 2012 and it consists of the UTM, CTM, Brinell Hardness testing machine, Spring testing machine, Impact testing machine etc. The laboratory is widely used for testing concrete cubes and cylinders and also to test the hardness and toughness of various materials used for construction which includes both steel and concrete. Various consultancy works are also extensively carried out in our lab.

The major equipment used in lab are:

- Universal Testing Machine(1000kN),

- Compression Testing Machine (2000kN)

- Impact Testing Machine

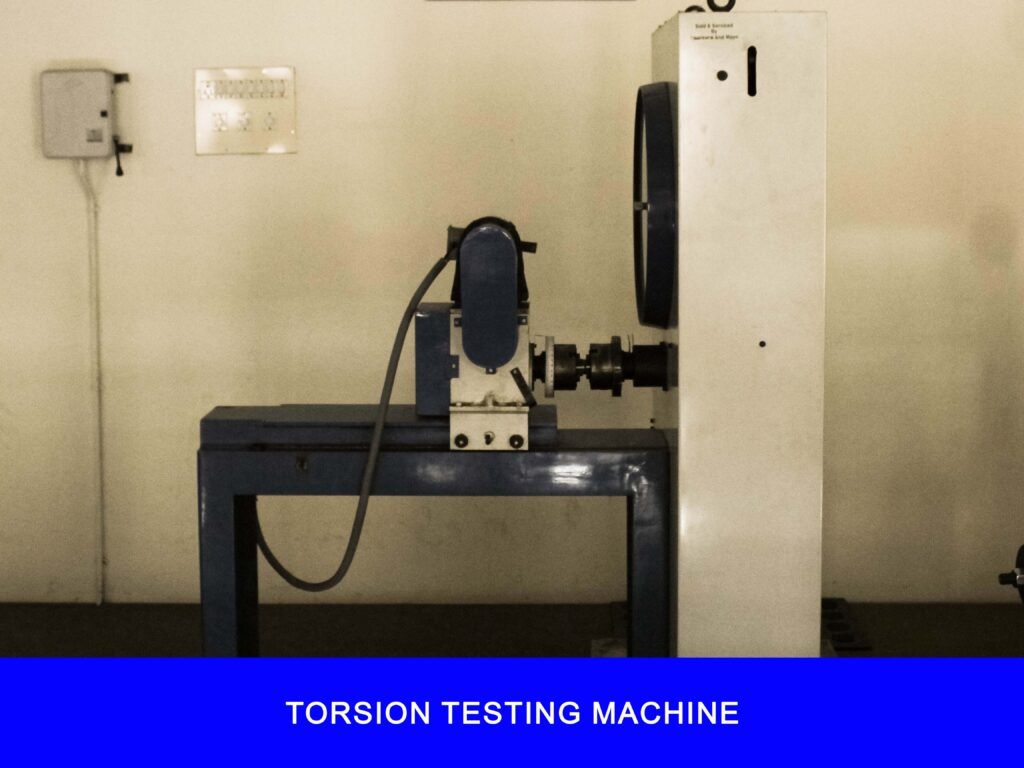

- Torsion Testing Machine(20kGm)

- Spring Testing Machine

- Hardness Testing Machine

- Tile Flexure Testing Machine

- Simple Torsion Pendulum

- VeeBee Consistometer

- Slump test apparatus

- Compaction Factor Testing Apparatus

- Vibrating Table

- Vicat Apparatus

- Rebound Hammer

- Sieve shaker

- Aggregate crushing value apparatus

- Cast iron cube mould (150mm,100mm,70.6mm)

- Cast iron Cylindrical mould (150x300mm)

- Le-chatelier apparatus

- Pycnometer

- Blaines air permeability apparatus

- Diamond cone intendor

- Displacement indicator

| List of Experiments – Material Testing | List of Experiments – Strength of Materials |

| Determination of the Specific Gravity of cement Determination of the Standard Consistency, Initial and Final Setting Times of Cement Determination of compressive strength of cement Tests on coarse and fine aggregate- Specific gravity, bulking, sieve analysis, fineness modulus, moisture content, bulk density Tests on Fresh Concrete: Workability, Slump test, Vee-Bee consistometer, Compaction factor tests Determination of Compressive Strength of Concrete Cube and Cylinder Determination of Split Tensile of Concrete Determination of Flexural strength of Concrete Determination of Compressive strength of Brick Determination of Transverse strength of roofing and flooring tiles Demonstration of Mix Design of Concrete by IS method Demonstration of Non-destructive tests (rebound hammer) | Tension test on Structural Materials: Mild Steel and Tor steel (HYSD bars) Shear test on mild steel rod Bending test on mild steel (I sections) Torsion test on Mild steel circular bars Torsion test on Steel/Copper/ Aluminum wires Using Torsion Pendulum with Central disk, Using Torsion Pendulum with distributed Mass Impact test Izod test Charpy test Hardness test Brinell Hardness test Rockwell Hardness test Vickers Hardness test Test on Springs-Open coil, Close coil Bending Test on Timber |

Lab in-charge

Faculty : Mr. Sunny C P

Lab Instructor : Mr Akhilesh C S

The planning and design of all Civil Engineering projects such as construction of highways, bridges, tunnels, dams etc are based upon surveying measurements. Thus, surveying is a basic requirement for all Civil Engineering projects.

The Surveying Laboratory is equipped with the instruments and tools that students use throughout the surveying course. Students learn techniques for gathering field data with both traditional and modern instruments and demonstrate their proficiency on weekly lab exercises and a comprehensive semester project and final exam. Each lab group – typically three to five students – has a dedicated set of instruments to use, including auto level, theodolite, and total station. Each group also has level rods, tripods, tape measures, chaining pins, and other common surveying tools and ancillary equipment. The lab serves as office space for the surveying instructor and teaching assistants, so surveying students have direct access to help for material discussed in lecture and lab.

The lab was setup in the year 2012.

Major equpiment available:

- Total station

- Theodolites

- Dumpy Level

- Prismatic compass

- Plane table

- Planimeter

- Pantograph

- Ghat tracer

- Box Sextant

- Abney Level

- Clinometer

- Levelling staff

- Hand level

- Automatic level

- Hand held GPS

- Metric chain(30m &20m) ,

- Cross staff

- Ranging rod

Lab in-charge

Faculty : Ms. Aiswarya M S

Lab Instructor : Mr. Clint Jain

The Geotechnical Engineering Laboratory is an integral part of the Department of Civil Engineering. The laboratory is equipped to perform all the necessary basic characterization of soils. Geotechnical engineering is the branch of civil engineering that deals with the engineering behavior of subsurface materials. It includes Soil Mechanics, which is essential to identify, characterize and study the mechanics of soil/rock and Applied Soil Mechanics, which transfers the behavioral knowledge to practice. This includes investigating existing subsurface conditions and materials; determining their engineering behavior that are important to the project considered and designing the foundations. A typical geotechnical engineering laboratory helps in identifying the engineering behavior of soil. Our Geotechnical Engineering Laboratory is well-equipped with equipments for evaluating all engineering properties of soils including index properties, compaction characteristics, consolidation characteristics and shear strength of soils.

We have Sieve Sets And Shakers, Direct shear Test Equipment, Consolidation apparatus, CBR testing apparatus, Cassagrande’s apparatus, UCC testing equipment etc. The lab was setup in the year 2013.

| List of Experiments | List of Equipment |

| Determination of Specific Gravity of Soil by Pycnometer method Field Density determination by sand replacement method Dry Sieve Analysis Determination of Atterberg Limits (Liquid limit, plastic limit and shrinkage limit) Determination of free swell index Direct Shear Test Permeability of Soil by Constant Head Method Permeability of Soil by Variable Head Method Unconfined compression Test Hydrometer Analysis Light Compaction Test ( Standard Proctor Test) Consolidation Test | Pycnometer Specific Gravity Bottle Sand Pouring Cylinder Sieve Set(4.75mm,3.35 Mm, 2.36mm,1.18mm,600μ, 300 μ, 150 μ, 90 μ, 75 μ) Casagrande Apparatus Shrinkage Limit Apparatus Direct Shear Apparatus Permeability Apparatus Unconfined Compression Test Apparatus Universal extractor frame Hydrometer Proctor Mould (Light And Heavy) Consolidation Apparatus Dynamic Cone Penetrometer Hand Auger Infra Red Moisture Meter Soil Cone Penetrometer Thermostatically Controlled Oven Electronic Weighing Balance Measuring jar/ cylinder Beaker |

Lab in-charge

Faculty : Ms. Haritha C R

Lab Instructor : Mr. Akhilesh C S

Computer Aided Design-CAD is defined the use of information technology (IT) in the Design process. A CAD system consists of IT hardware (H/W), specialised software (S/W) (depending on the particular area of application) and peripherals, which in certain applications are quite specialised. The core of a CAD system is the S/W, which makes use of graphics for product representation; databases for storing the product model and drives the peripherals for product presentation. Its use does not change the nature of the design process but as the name states it aids the product designer. The designer is the main actor in the process, in all phases from problem identification to the implementation phase.

These days the use of software for drafting and designing has become very important and easy. And they are mandatory for our students for their future. Here the students are coached in drafting using Auto CAD and design using STAAD.Pro

Hardware available:

- Desktop- 60 nos. (Intel(R) core (TM) i3, 4GB RAM, 64- bitOS, x64-based processor), 500 GB HDD, 18” Monitor

- Projector

Software available:

- AutoCAD 2019

- Revit 2020

- STAAD.Pro Connect Edition

- Microsoft Project

- Autodesk Fusion 360

- Microsoft Office

Lab in-charge

Faculty : Mr. Akhil S Nair

Lab Instructor : Ms. Mini K R

The environmental engineering laboratory offers students, hands-on exposure to EPA approved water and wastewater quality testing procedures as is normally done at a water and wastewater treatment plant. It is equipped with state of the art gas chromatograph, UV spectrophotometers, turbidimeter, COD reactors, BOD incubators, bacterial incubators, pH meters, conductivity meters, dissolved oxygen probe, digital titrators and other equipment dedicated to water and wastewater quality analysis. Our lab was setup in the year 2014. The students are encouraged to do projects related to water quality testing and they use the facilities of lab extensively. We also undertake consultancies related to water quality testing.

| List of equipment | List of experiments |

| Hot air oven Digital turbidity meter Flocculator – jar test apparatus Digital pH meter Digital spectrophotometer BOD incubator Heating mantle Reflex apparatus Water still, Digital top pan balance Magnetic stirrer Microprocessor (Conductivity meter) | Analysis of physical characteristics viz. colour, turbidity, and conductivity of a water sample Analysis of chemical characteristics of a water sample viz. pH, acidity, alkalinity, chlorides and sulphates. Determination the Dissolved Oxygen content in a water sample Determination of available chlorine in a sample of bleaching powder Determination of BOD of wastewater sample Determination of COD of wastewater sample Determination of optimum dosage of alum using Jar test Determination of Nitrates / Phosphates in a water sample Determination of iron content of a water sample Determination of MPN content in a water sample |

Lab in-charge

Faculty : Ms. Sujana R

Lab Assistant : Ms. Mini K R

The transportation engineering laboratory is equipped with well maintained experimental set ups for determining the various characteristics of the bitumen and coarse aggregates that are used for the pavement construction. Transportation engineering is a specialization in Civil Engineering that deals with the planning, functional design, operation and management of facilities for any mode of transportation in order to provide a safe, efficient, rapid, comfortable, convenient, economical, and environmentally compatible movement of people and goods. The design aspects of transportation engineering include the sizing of transportation facilities, determining the materials and thickness used in pavement and designing the geometry of the roadway. The various equipment available in the laboratory are Impact testing machine, Los Angeles Abrasion Testing Machine, Flakiness and Elongation Index test setup, Angularity Index test set up, Specific Gravity and Water Absorption testing apparatus, Ductility machine and Briquiette mould, Ring and ball apparatus, Bitumen Penetrometer and Stripping value apparatus. This laboratory course will help the students to assess the suitability of the materials for pavement construction.

| List of Experiments | List of Equipment |

| Impact Test Los Angeles Abrasion Test Shape Test – Flakiness Index Shape Test – Elongation Index Aggregate Crushing Test Penetration Test Softening Point of Bitumen Ductility Test California Bearing Test Specific Gravity of Coarse Aggregate Water Absorption of Coarse Aggregate Stripping Value of Road Aggregates Angularity of Coarse Aggregate and Fine Aggregate | Impact testing machine Los Angeles machine Standard Thickness Gauge Length Gauge Compression Testing Machine Penetrometer Ring and Ball Apparatus Bitumen ductility test apparatus Briquette Mould CBR Test Apparatus Pensky Martens flash point apparatus Wire Basket Thermostatically Controlled Oven Heater and Pan Metal Cylinder and Tamping rod I.S. sieves of sizes 63, 50, 40, 31.5, 25, 20, 16, 12.5, 10 and 6.3mm Electronic Weighing Balance |

Lab in-charge

Faculty : Ms. Ragi C Ravindran

Lab instructor: Mr. Clint Jain

Civil engineers generally work in a variety of locations and conditions. Many spend time outdoors at construction sites so that they can monitor operations or solve problems onsite. The job is typically a blend of in-office and on-location work. To give insight into these aspects of Civil Engineering, the students of all disciplines are exposed to such an environment in their First year curriculum through Civil Engineering Workshop.

Major equipment available:

- Shovel

- Trowel

- Float

- Plumb Bob

- PVC pipe, Reducer, Shower, PVC tap, Bend, Elbow, Ball valve

- Tri square

- Tape

- Spirit level

- Plier

- Hammer

- Straight Edge

- Minidrafter

Lab in-charge

Faculty: Ms. Gokila Chandran

Lab Instructor : Mr Clint Jain

| List of equipment | List of experiments |

| Orifice meter Venturimeter Laboratory flume Triangular notch Rectangular notch Bernoulli's apparatus Centrifugal pump Pelton wheel turbine Francis turbine | Verification of Bernoulli’s theorem Hydraulic coefficients of orifices and mouth pieces under constant head method and time of emptying method. Calibration of Venturimeter Calibration of Orifice meter Calibration of rectangular notch Calibration of triangular notch Time of Emptying through Orifice Determination of metacentric height and radius of gyration of floating bodies Plotting Specific Energy Curves in Open Channel flow Study of Parameters of Hydraulic Jump in Open channel Flow |

Lab-in-charge

Faculty: Riya Susan Andrew

Lab instructor: Aashik P. Pankaj